54” I.D. x 20’ S/S 1440psi 4 Phase Skidded Test Separator Package

54” I.D. x 20’ S/S 1440psi 4 Phase Skidded Test Separator Package está agotado y se enviará tan pronto como vuelva a estar disponible.

No se ha podido cargar la disponibilidad de recogida

For detailed specifications, please click on the "plus" icon to open each section below

Description:

54” I.D. x 20’ S/S 1440psi 4 Phase Skidded Test Separator Package

Condition:

Used – Lightly

Location:

Alberta, Canada

Price

$300,000 USD each. (3 Identical Units Available)

Warranty:

No Warranty (Sale is As-Is, Where-Is Unless Refurbishment Quoted & Accepted)

Dimensions:

Width 122.25” (3,105 mm)

Length 444” (11,278 mm)

Height 132.25” (3,359 mm)

Weight:

68,000 lbs (30,844 kg)

Tag:

V-101

Diameter:

54” I.D. (1,372 mm)

Length:

20’ S/S (6,098 mm)

MAWP:

1440 psi (9,928 kPa)

Design Temp:

130 F (54.44 C)

MDMT:

-50 F (-45.55 C)

C/A:

0.125” (3.16 mm)

Volume:

62 BBL (9.86 m3)

Phases:

4 Phase (Two Weirs – First Two Compartments c/w Sparge System)

Orientation:

Horizontal

PWHT:

Yes

Radiography:

RT-1

Year Built:

2012

Built By:

DynaCorp Fabricators

Heating Coil:

Yes – 4” single unit with (2) 1” Fig. 206 inlet/outlet connections

Sparge Piping:

Yes – (2) 1” 600# RF Nozzles c/w Tapped Hub Blind & 1” NPT 6M Ball Valve w/ Hex Plug

NOTE:

In February 2020 the vessel was re-rated to 1360 psi @ 195 F (9,377 kPa @ 90.55 C) through ABSA to achieve a higher vessel design temperature to work on high temperature wells. The original design pressure and temperature is still valid.

NOZZLE SCHEDULE:

| ID# | SIZE & RATING | SERVICE |

|---|---|---|

|

N1 |

6” – 600#RF |

Inlet |

|

N2 |

6” – 600#RF |

Gas Outlet |

|

N3 |

3” – 600#RF |

PSV |

|

N4 |

3” – 600#RF |

Oil LC |

|

N5 A/B |

1” – 600#RF |

Oil LG |

|

N6 |

3” – 600#RF |

Oil Outlet |

|

N7 |

3” – 600#RF |

H2O LC |

|

N8 A/B |

1” – 600#RF |

H2O LG |

|

N9 |

3” – 600#RF |

H2O Outlet |

|

N10 A/B |

1” – 600#RF |

Inlet LG |

|

N11 A/B |

3” – 600#RF |

Drains |

|

N12 |

1” – 600#RF |

LSHH |

|

N13 |

1” – 600#RF |

PI |

|

N14 |

1” – 600#RF |

TI |

|

N15 |

4” – 600#RF |

Heat Coil |

|

N16 A/B |

1” – 600#RF |

Sparge |

|

M1/M2 |

20” – 600#RF |

Manways |

- Switch High High (LSHH-101)

- Level Alarm High (LAH-101)

- Level Switch Low Low (LSLL-101)

- Pressure Indicator (PI-100)

- Pressure Switch Low (PSL-101)

- Pressure Switch High (PSH-101)

- Temperature Indicator w/ Thermowell (TI/TW-105)

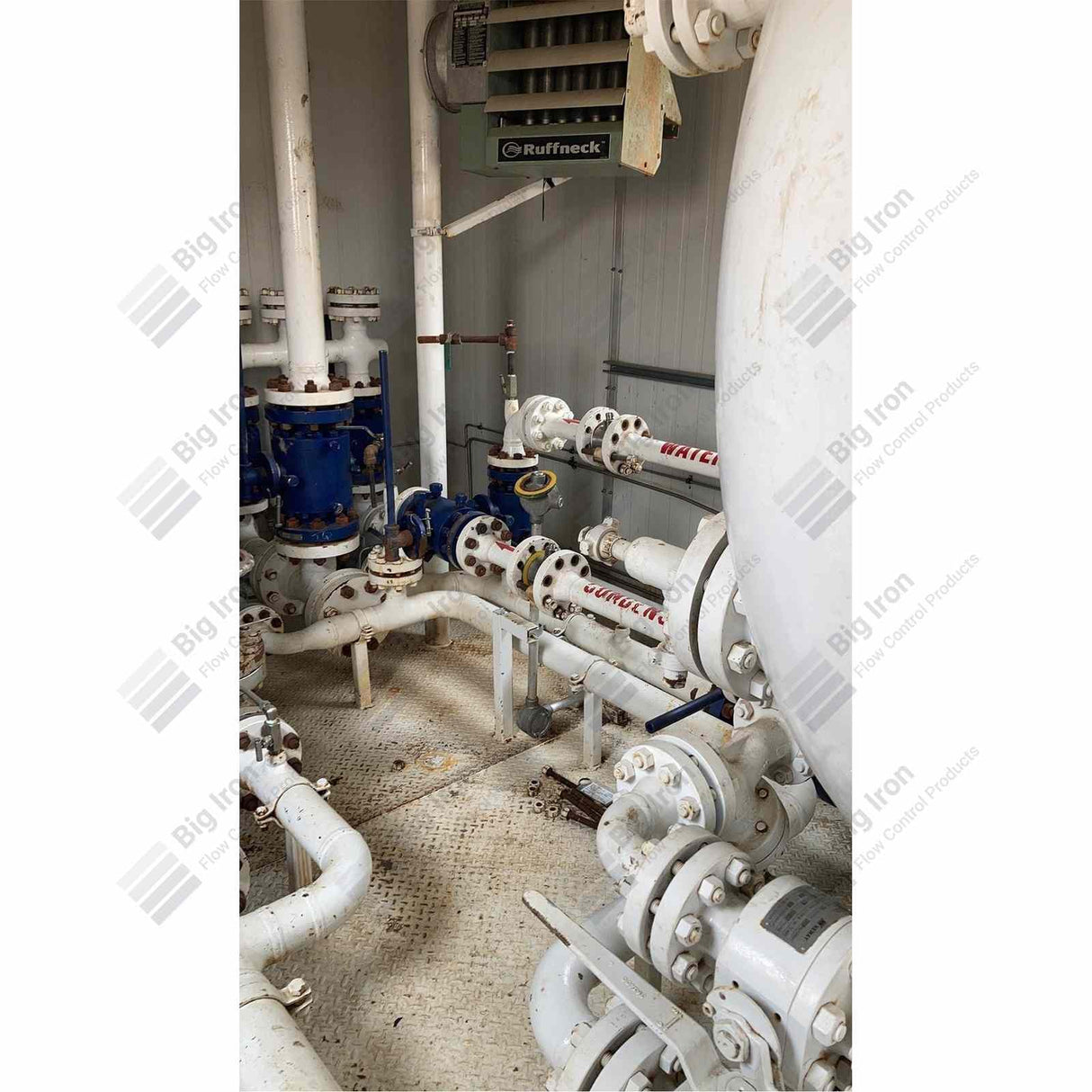

- 3” 1502F skid edge connection c/w 3”1502M cap w/ ½” tap & needle valve

- “M1” Manifold Connection Point

- Isolation Valve 4” 600# RF Ball Valve

- Branch connection to Inlet By-Pass Manifold c/w 3” 600# RF Ball Valve

- Removable flanged cushioned tees for elbows allow quick replacement of blind flange end or entire flange tee in the event of a wash out.

- ½” High point vent included on top of inlet piping c/w ½” hex plug

- Inlet Diffuser installed in vessel inlet nozzle

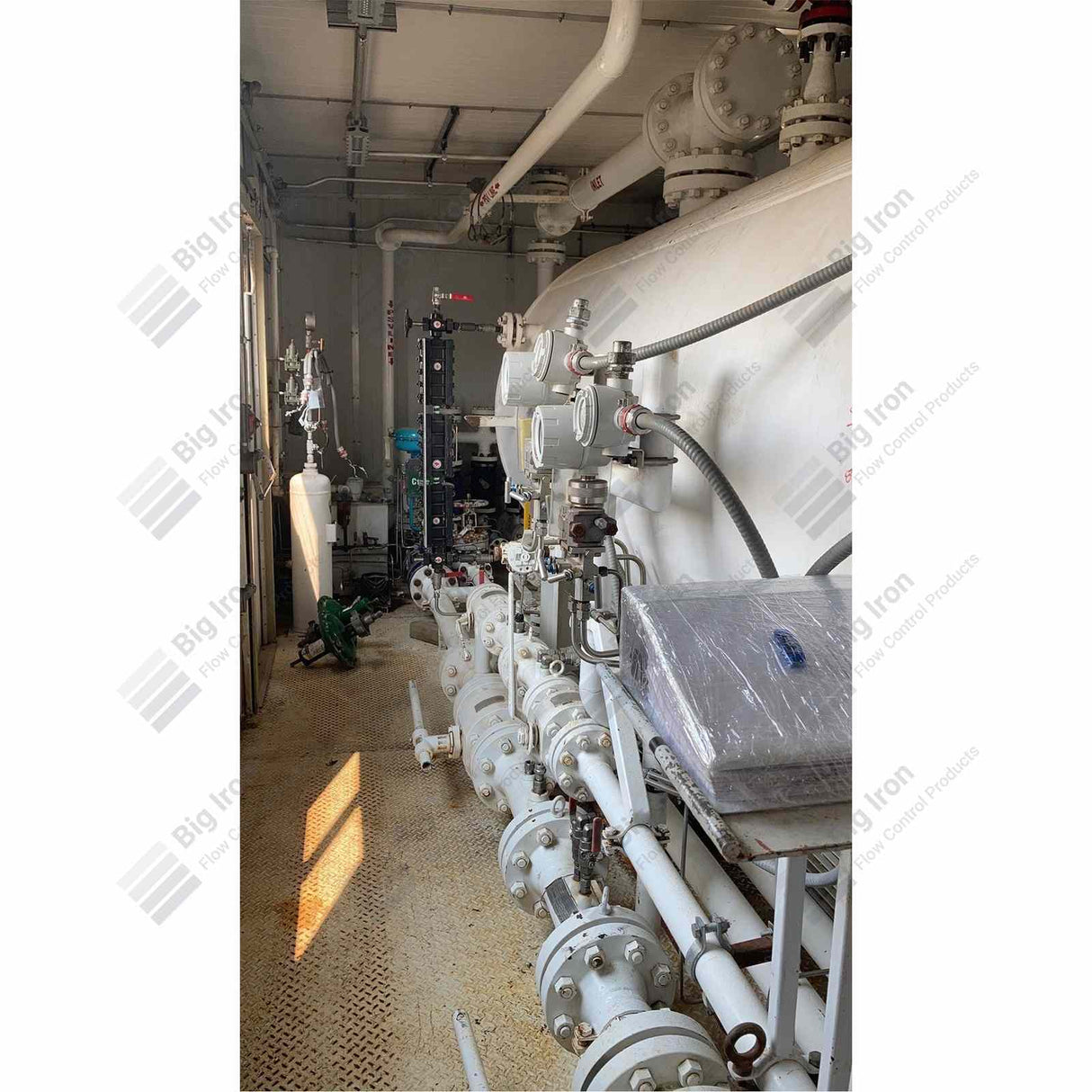

- Gas Demister installed at vessel gas outlet nozzle

- 6” 600#RF Gas outlet piping then reduced to 4” 600#RF upstream of gas meters

- The 4” 600#RF piping is split into two Gas Meters, one is 4” and the other is 2”.

- Meter #1 (FE-101)

- (1) 4” 600#RF Flanged V-Cone Gas Meter

- (2) ½” Full Port ball valves installed on V-Cone pressure taps and SST tubing to 5 valve manifold / flow computer

- (1) Cameron NUFLO Scanner 2000 microEFM Flow Computer

- (1) RTD installed d/s of Meter and wired to Scanner 2000

- (1) Extra thermowell installed downstream of RTD for manual temperature readings

- (1) 5 valve manifold, Stainless Steel, vented to PSV discharge line

- (2) Isolation Ball Valves 4” 600#RF installed up & downstream of meter run

- Gas Meter #2 (FE-102)

- (1) 2” 600#RF Flanged V-Cone Gas Meter

- (2) ½” Full Port ball valves installed on V-Cone pressure taps and SST tubing to 5 valve manifold / flow computer

- (1) Cameron NUFLO Scanner 2000 microEFM Flow Computer

- (1) RTD installed d/s of Meter and wired to Scanner 2000

- (1) Extra thermowell installed downstream of RTD for manual temperature readings

- (1) 5 valve manifold, Stainless Steel, vented to PSV discharge line

- (2) Isolation Ball Valves 2” 600#RF installed up & downstream of meter run

- The 4” and 2” 600#RF lines from the gas meters are combined into a single 4” 600#RF line then routed to the Back Pressure Control Valve (BPCV-101).

- Upstream of the BPCV-101, the piping is branched off into a 3” control valve by-pass.

- BPCV Isolation

- (1) Isolation Ball Valve 4” 600#RF installed upstream

- (1) Isolation Globe Valve 4” 600#RF installed downstream

- BPCV By-Pass

- (1) Globe Valve 3” 600#RF

- Backpressure Control Valve (BPCV-101)

- (1) 3” 600#RF CVS Control E Series Control Valve

- c/w CVS 657 Size 45 Direct Acting (Fail Open) Actuator

- Trim: TBC

- Pressure Controller (PC-101)

- (1) Fisher C1 Low Emission Pressure Controller

- Sensing line tubed to upstream location

- Supply line tubed from Fuel Gas System

- The 4” line from BPCV-101 and the 3” 600#RF By-Pass lines are then tied together with a 3” 600#RF line and then run in parallel to skid edge. The 4” line is the “Sales Gas Outlet” and the 3” line is the “Flare Gas Outlet”. Both of these outlets are connected to each other and include isolation valves in the event inline operations need to be switched to flaring.

- The 4” “Sales Gas” line from BPCV-101 is then reduced to 3” 600#RF and is then branched off into the 3” 600#RF Inlet By-Pass Manifold c/w Isolation Ball Valve 3”600# RF

- After the branch for the Inlet By-Pass Manifold, the 3” 600#RF “Sales Gas” line is routed to skid edge. Included at skid edge is a 3” 600# RF Isolation Ball Valve then a cross over flange from 3” 600#RF to Fig. 206 M c/w Fig. 206 F Blanking cap for transportation.

- The 3” 600#RF “Flare Gas” line is routed to skid edge. Included at skid edge is a 3” 600# RF Isolation Ball Valve then a cross over flange from 3” 600#RF to Fig. 206 M c/w Fig. 206 F Blanking cap for transportation.

- Also included upstream of the isolation ball valve is “M5” Manifold Connection Point.

- Water Level Control and Level Gauges

- The water level is controlled using (LC-101) a Fisher L2 liquid level controller using a displacer type sensor to detect the interface of the water and oil phases inside the vessel upstream of the last weir.

- (2) level gauges “sight glasses” are provided for the water phases in the vessel. LG-101 is located upstream of the first weir and LG-102 is located upstream of the last weir.

- Both Level Gauges include ½” Drain Ball Valves and are tubed to common drain header and liquid volume gauge board mounted beside Level Gauge.

- LG-101 consists of (3) sections of TM5 Transparent Level Gauges, (1) Set of two ¾”x1/2” gauge cocks, (2) Isolation Ball Valves ¾” NPT 2M and (2) 1” 600# RF Nozzles c/w Tapped Hub Blind ¾” FNPT

- LG-102 consists of (2) sections of TM5 Transparent Level Gauges, (1) Set of two ¾”x1/2” gauge cocks, (2) Isolation Ball Valves ¾” NPT 2M and (2) 1” 600# RF Nozzles c/w Tapped Hub Blind ¾” FNPT

- The water outlet includes a Vortex breaker in vessel.

- A 3” 600#RF nozzle is used for the water outlet connection. From this nozzle 3” 600#RF piping is routed to both the drain header and water metering / skid edge. Both lines include Isolation Ball Valves. Between the two isolation valves is “K” Chemical Injection Point

- Downstream of the Isolation valve the 3” 600#RF main water outlet line is branched off into a 2” 600#RF for the flow meter than recombined back into the 3” line. The branch run includes:

- (2) Isolation Ball Valve 2” 600#RF

- (2) High Point vents c/w ½” NPT hex plugs

- (1) Wye- Strainer 2” 600# RF Flanged c/w ½” NPT 2M drain ball valves tubed back into water line downstream of the level control valve.

- (1) Cameron Nuflo EZ-IN 2” 600#RF wafer style liquid turbine flow meter, c/w magnetic pick up, 3” extension and centralizers

- (1) Cameron Nuflo MCIII EXP Totalizer

- After the upstream liquid meter branch connection, the 3” line c/w 3” 600#RF Isolation Ball valves which is Normally Closed. This valve is used when by-passing the liquid meter is required.

- Once the 2” liquid meter line is recombined into the 3” line, the 3” line is then reduced down to 2” and it is routed to LCV-202 the Water Level Control Valve.

- Water Level Control Valve (LCV-202)

- (1) 2” 600#RF Fisher D4 Dump Valve

- c/w Reserve Acting (Fail Closed) Actuator

- Trim: TBC

- After the Water Level Control Valve (LCV-202) the 2” line is increased to 3” 600#RF and is then branched off into the 3” 600#RF Inlet By-Pass Manifold c/w Isolation Ball Valve 3”600# RF

- The 3” 600#RF “Water Outlet” line is routed to skid edge. Included at skid edge is a 3” 600# RF Isolation Ball Valve then a cross over flange from 3” 600#RF to Fig. 206 M c/w Fig. 206 F Blanking cap for transportation.

- Also included upstream of the isolation ball valve is “M3” Manifold Connection Point.

- Oil Level Control and Level Gauge

- The oil level is controlled using (LC-102) a Fisher L2 liquid level controller using a displacer type sensor to detect the level height of oil phase inside the vessel downstream of the last weir.

- (1) level gauge “sight glass” are provided for the oil phase in the vessel. LG-103 is located downstream of the last weir.

- Level Gauge include ½” Drain Ball Valves and is tubed to common drain header and liquid volume gauge board mounted beside Level Gauge.

- LG-103 consists of (2) sections of TM5 Transparent Level Gauges, (1) Set of two ¾”x1/2” gauge cocks, (2) Isolation Ball Valves ¾” NPT 2M and (2) 1” 600# RF Nozzles c/w Tapped Hub Blind ¾” FNPT

- The oil outlet includes a Vortex breaker in vessel.

- A 3” 600#RF nozzle is used for the water outlet connection. From this nozzle 3” 600#RF piping is routed to both the drain header and oil metering / skid edge. Both lines include Isolation Ball Valves. Between the two isolation valves is “Z” Chemical Injection Point

- Downstream of the Isolation valve the 3” 600#RF main oil outlet line is branched off into a 2” 600#RF for the flow meter than recombined back into the 3” line. The branch run includes:

- (2) Isolation Ball Valve 2” 600#RF

- (2) High Point vents c/w ½” NPT hex plugs

- (1) Wye- Strainer 2” 600# RF Flanged c/w ½” NPT 2M drain ball valves tubed back into the oil line downstream of the level control valve.

- (1) Cameron Nuflo EZ-IN 2” 600#RF wafer style liquid turbine flow meter, c/w magnetic pick up, 3” extension and centralizers

- (1) Cameron Nuflo MCIII EXP Totalizer

- After the upstream liquid meter branch connection, the 3” line c/w 3” 600#RF Isolation Ball valves which is Normally Closed. This valve is used when by-passing the liquid meter is required.

- Once the 2” liquid meter line is recombined into the 3” line, the 3” line is then reduced down to 2” and it is routed to LCV-201 the Oil Level Control Valve.

- Oil Level Control Valve (LCV-201)

- (1) 2” 600#RF Fisher D4 Dump Valve

- c/w Reserve Acting (Fail Closed) Actuator

- Trim: TBC

- After the Oil Level Control Valve (LCV-201) the 2” line is increased to 3” 600#RF and is then branched off into the 3” 600#RF Inlet By-Pass Manifold c/w Isolation Ball Valve 3”600# RF

- The 3” 600#RF “Oil Outlet” line is routed to skid edge. Included at skid edge is a 3” 600# RF Isolation Ball Valve then a cross over flange from 3” 600#RF to Fig. 206 M c/w Fig. 206 F Blanking cap for transportation.

- Also included upstream of the isolation ball valve is “M4” Manifold Connection Point.

- On the upstream side of the first weir (dirty side) there are (2) two 3” 600#RF drain connections on the bottom of the vessel. Each drain connection has an Isolation Ball Valve 3” 600#RF. Between the vessel and isolation valves are Chemical Injection Points “W” and “X” (one each).

- Downstream of the Isolation Ball Valves the lines are combined into the common drain header and is then branched off into the 3” 600#RF Inlet By-Pass Manifold c/w Isolation Ball Valve 3”600# RF

- The 3” 600#RF Drain line is routed to skid edge. Included at skid edge is a 3” 600# RF Isolation Ball Valve then a cross over flange from 3” 600#RF to Fig. 206 M c/w Fig. 206 F Blanking cap for transportation.

- Also included upstream of the isolation ball valve is “M2” Manifold Connection Point.

- The vessel is fitted with a sparge system designed to accept high pressure water which is routed to a coil on the inside lower portion of the vessel. The high pressure water is sprayed from the sparge coil into the vessel to break up accumulated solids which are removed through the drain nozzles.

- The vessel and process piping are protected from over pressurization by (1) Pressure Safety Valve (PSV-101). The PSV nozzle on the vessel is 3” 600#RF and piping reduced to 2” upstream of PSV-101.

- PSV-101 Pressure Safety Valve

- Axelson Model: 9A-46030-311A35Y

- 2” 600# RF x 3” 150# RF

- Pilot Operated

- G Orifice

- Set @ 1440 psi (9928 kPa)

- Capacity: 41,109 SCFM

- The 3” 150#RF PSV Discharge line is routed to skid edge. Included at skid edge is a cross over flange from 3” 1500#RF to Fig. 206 M c/w Fig. 206 F Blanking cap for transportation.

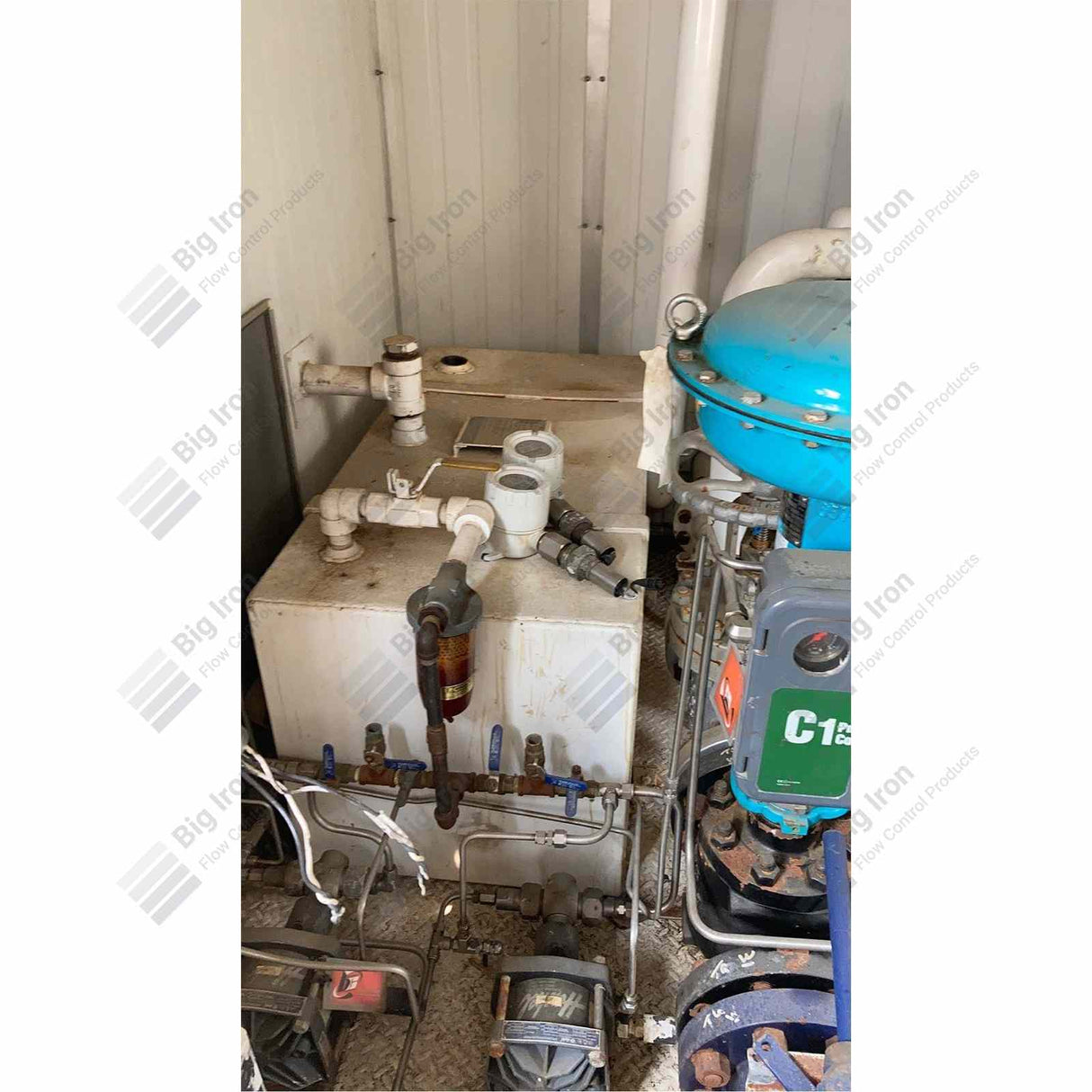

- The Instrument Air Scrubber inlet piping starts at Skid edge with 1” NPT Union to be connected to off skid air supply by others. The pressure reducing valve PRV-201 is located on the 1” inlet line and reduces the pressure to take set by the operator.

- The scrubber and related process piping are protected from over pressurization by (1) Pressure Safety Valve (PSV-103). The PSV is located on the inlet piping of the Instrument Air Scrubber downstream of PRV-103.

- PSV-103 Pressure Safety Valve

- Taylor Valve Model: 82E4351311

- 1” MNPT x 1” FNPT

- Convention Type PSV

- E Orifice

- Set @ 150 psi (1034 kPa)

- Capacity: 582 SCFM

- The 1” PSV Discharge line is routed to skid edge and discharges to atmosphere near the roof line.

- Installed in the outlet of the Instrument Air Scrubber is a high level shut off float. The purpose of this float is that as the vessel fills with liquid, the liquid will raise the float and once it reaches the top of its travel limit the float will block the flow of air out of the scrubber. The benefit to this shut off is that it prevents unwanted liquid from entering the instrumentation air supply lines and eventually entering the instruments and devices.

- After the high level shut off, there is an instrument air manifold installed on top of the scrubber. Here there are (6) branches, each with its own pressure reducing regulator (PRV-101 to 106). Each of these PRVs is responsible for air supply to a specific instrument.

- On the top of the instrument air manifold in a pressure indicator (PI-201) c/w ½” NPT needle valve.

Instrument Air Scrubber:

Tag:

V-103

Diameter:

6.065” I.D. (154 mm)

Length:

36” S/S (914 mm)

MAWP:

150 psi (1,034 kPa)

Design Temp:

649 F (343 C)

MDMT:

-20 F (-18.88 C)

C/A:

Nil” (Nil mm)

Volume:

x BBL (x m3)

Phases:

2 Phase

Orientation:

Vertical

PWHT:

No

Radiography:

No

S/N:

1007.11567

Year Built:

2012

Built By:

LO TECH MANUFACTURING

NOZZLE SCHEDULE:

| ID# | SIZE & RATING | SERVICE |

|---|---|---|

|

N1 |

1” – CLR 2M |

Inlet |

|

N2 |

1” – CLR 2M |

Outlet |

|

N3 |

3/4” – CLR 2M |

Drain |

- This unit is equipment with a chemical injection system that consists of the following equipment

- (2) Methanol Pumps (P-101 and P-102)

- Haskel

- Air Driven

- Xx GPM (xx LPM)

- Max Pressure: 10,000 psi (68,950 kPa)

- (1) Chemical Storage Tank (T-800)

- 500 gal. (1893 liters)

- Pressure Relief Valve 7 psi / 0.5 psi Vacuum

- The 1” NPT outlet line from the Chemical storage tank is routed through a filter than into the Chemical Pumps suction header.

- The Pumps, HP chemical injection manifold and related tubing lines are protected from over pressurization by (1) Pressure Safety Valve (PSV-301). The PSV is located on the inlet of HP chemical injection manifold downstream of P-101 and P-102.

- PSV-301 Pressure Safety Valve

- Brand: Unknown Model: TBC

- 1/4” MNPT x 1/4” FNPT

- Set @ 1440 psi (9928 kPa)

- The 3/8” PSV Discharge Tubing line is routed to the suction header for both pumps.

- Alarms

- LAH-101 is wired to exterior mounted Junction Box with a two position hand switch to enable or overside & silence the visual red beacon and audible siren alarm.

- Shutdowns

- PSL-101 / PSH-101, LSHH-101 and LSLL-101 are all pneumatic switches which are tubed back to an external mounted Junction Box with panel mounted indicators for Lo Level, Hi Level, Hi/Lo Pressure.

- This junction box has two tubing connections, the first for air or nitrogen to charge the system and the second is to be connected to a pneumatic actuator mounted on an ESD valve located at the well head on the flow line

Style:

Oilfield Rollend

Width:

122.25” (3,105 mm)

Length:

444” (11,278 mm)

Type:

Unit is fully enclosed in single building

Style:

Foam Panel Construction

Width:

122.25” (3,105 mm)

Length:

444” (11,278 mm)

Height:

132.25” (3,359 mm)

Heaters:

Yes – (2) Electric Ruffneck Model: xxxx

- Building can be removed, and gas spools removed for transport to reduce height

- Refurbishment, retrofit, repackaging to customer specifications available upon request

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.